Ding Zan Precision Molds: The Artisan of the Mold Industry, Crafting Unique Solutions for Clients

Table 3-16 Introduction to Ding Zan Precision Molds Industry Co., Ltd.

|

Company Name |

Ding Zan Precision Molds Industry Co., Ltd. |

|

Company Brands |

DZ, DING ZAN |

|

Incorporated Date |

1995 |

|

Business Vision |

Innovation, Quality, Responsibility. |

|

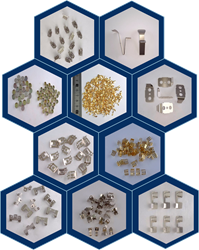

Company Attributes |

1. Metal mold manufacturing facility operating with a standard job-shop production model. 2. Specializing in the research, development, and production of mold-related products through a diversified operational approach. Core business areas encompass the design and manufacturing of precision stamping molds, 3C electronic components, high-precision terminals, spring contacts, semiconductor carriers, industrial hardware, household hardware, and components for pneumatic and electric tools. |

|

Core Capabilities |

Target Market: We specialize in high-quality precision mold design and manufacturing services, catering to clients across industries that demand superior accuracy and quality. Additionally, we serve small and medium-sized enterprises that require flexible production capabilities and timely delivery. While our primary focus is currently on the domestic market, we aim to gradually expand into international markets as industry conditions evolve, with the goal of increasing our export share over time. Product Quality: Quality is our top priority in both manufacturing and service, and we continuously innovate across the development, design, and production stages to ensure that every mold meets the highest standards. Our capabilities include stamping and processing molds made from a wide range of materials, such as nickel alloys, titanium alloys, aluminum alloys, stainless steel, high-carbon steel, and non-metallic materials; bakelite and plastic, enabling us to meet diverse customer needs. Since 2001, we have expanded into the semiconductor packaging equipment field, earning certification as a qualified supplier due to the stability and quality of our carrier production. In 2004, we began developing a series of improved, patented semiconductor packaging carriers, solidifying our position as a key supplier in the precision mold industry. |

|

Future Prospects |

We are continuously driving the company's transformation and upgrading efforts, aiming to achieve a vision of sustainable operation through measures such as legalizing factory premises, ensuring compliance of facilities, involving second-generation successors, expanding investments, and enhancing employee quality. |

Ding Zan Precision Molds is a fully integrated operation specializing in mold development and production, committed to delivering efficient mold solutions across industries such as semiconductors, electronics, and hardware. The company has earned the trust of its clients through industry-leading, high-precision mold technology. As global market competition intensifies, Ding Zan is actively pursuing transformation and upgrades, leveraging technological innovation and design expertise to provide clients with increasingly valuable products and services.

Target Customers and Market

Ding Zan focuses on the domestic market, offering services in manufacturing metal and non-metal components, including kitchenware and hardware. Its main business includes: designing custom precision molds using advanced software and techniques; collaborating with clients on product development from concept to realization with comprehensive technical support; and providing technical consulting and professional advice to help clients improve production efficiency.

Recognized for its technical expertise, the company has transformed from simple contract manufacturing to becoming a supplier for major electronics companies, handling various ODM and OBM orders. As the industry environment evolves, the company is now targeting small and medium-sized enterprises with smaller but steady demand. While their order volumes may not attract large manufacturers, they present opportunities for Ding Zan to deliver flexible, tailored services. The company is also driving transformation by investing in factory construction and advanced equipment, with a goal to achieve ISO certification and expand its customer base, particularly in the electronics and automotive industries.

Leadership and Management Strategy

Ding Zan has been in business for nearly 30 years. Founder Mr. Chen Wen-shi adopted a "small but refined" strategy, focusing on meeting the order demands of small and medium-sized enterprises to leverage the company’s competitive advantage. Observing that many companies in the industry lack design capabilities and can only manufacture based on client designs—limiting profitability to sustain operations - he anticipates possible industry consolidation, which could present an opportunity for the company. This has motivated Ding Zan’s active pursuit of transformation.

The founder emphasizes effective management of production processes and data, establishing internal SOPs to ensure sustainable development. In terms of talent management, the company values employee welfare and believes that a profit-sharing system can motivate and retain talent. In the future, alongside gradually transitioning the business to second-generation leadership, the founder plans to invest in equipment and human resources, build a business development team, standardize operations, and promote the company’s technical expertise and capabilities.

Key Technologies and Service Models

Ding Zan’s’ main competitive advantages lie in its advanced design and manufacturing capabilities for precision molds. Since its inception, the company has utilized cutting-edge CAD design software to ensure mold precision consistently meets exacting standards. Through ongoing technological breakthroughs, Ding Zan has successfully undertaken numerous challenging projects, earning market trust and recognition. Its specialized expertise later positioned the company as a key supplier in the production supply chain for large manufacturing plants, opening doors to long-term partnerships.

In addition, Ding Zan prioritizes automation in its production processes. The automated system is equipped with an immediate shutdown feature to prevent defective products from entering the market, enhancing product reliability and minimizing waste. The company’s flexibility in offering customized solutions, tailoring products to client specifications, and providing excellent real-time responsiveness has been instrumental in establishing a strong foothold in this highly competitive industry.

R&D Innovation

Ding Zan has been consistently dedicated to research and development, driving technological innovation to ensure the reliability and durability of its molds through precision machining and rigorous quality control. The founder believes that mold design requires not only creativity but also exceptional precision. While structural innovation can improve efficiency, the primary focus is on meeting customers' demands for accuracy and production speed. Along with advanced production equipment and software tools, the company places a strong emphasis on having R&D personnel with specialized expertise. Since mold development demands continuous learning and knowledge accumulation, staff must be skilled at gathering and analyzing data to deepen their technical knowledge. For knowledge that cannot be easily conveyed verbally, the founder has also begun developing comprehensive manuals to support knowledge transfer and the training of future employees, enabling them to quickly build expertise and acquire well-rounded technical skills.

Brand Strategy

Ding Zan understands that product quality directly impacts the company’s reputation, which is why it strictly controls every detail of the production process. This commitment to quality has earned the company a strong market reputation, building trust with existing clients and establishing long-term partnerships. Additionally, through word-of-mouth recommendations and referrals from previous clients, the company has attracted many potential customers.

To expand its business, the company also plans to enter international markets. The founder has observed that the global mold industry is facing similar challenges related to modernization and succession, which may lead to a reduction in the number of companies in the future. As a result, Ding Zan is exploring digital marketing and participating in trade exhibitions to promote its brand internationally. Finally, the company also places great emphasis on social responsibility, actively participating in charitable activities, supporting educational initiatives, and prioritizing environmental protection, thereby presenting a positive corporate image in the market.

Industry Challenges and Development Strategies

Labor shortages are one of the challenges facing the manufacturing industry, particularly the training and retention of technical personnel. Due to the complexity of precision mold technology, workers require long-term training to become proficient. Additionally, the younger generation's preference for more comfortable work environments has exacerbated the talent shortage in the industry. Although the government has attempted to fill the labor gap with foreign workers, training foreign labor is relatively difficult, making it hard to resolve the technical workforce issue at its core.

Furthermore, Taiwan has many small-scale mold manufacturing companies that lack development capabilities and rely heavily on contract manufacturing. During economic downturns, these companies are at risk of closure. In contrast, precision molds have higher entry barriers, relying on technology rather than price, and offer higher profits. However, the global economic downturn still places significant pressure on Ding Zan. As a result, the company must seek breakthroughs in technological and product differentiation to enhance its competitive advantage.

Conclusion

Ding Zan Precision Molds has successfully established itself as an industry leader through innovation in research and development and exceptional product quality. The company prioritizes talent development and continuously upgrades its precision manufacturing technologies to deliver efficient and reliable solutions to customers. Additionally, Ding Zan emphasizes social responsibility, fostering a strong corporate image. Amid increasing industry challenges, the company remains committed to a customer-centric philosophy, pursuing long-term growth and striving to become a leading global enterprise.

Facebook

Facebook

Twitter

Twitter

LINE

LINE