SA CHEN STEEL MOLD CO., LTD: Committed to Quality and Innovation, Providing High-Precision Mold Solutions Globally

Table 3-5 Introduction to SA CHEN STEEL MOLD CO., LTD

|

Company Name |

SA CHEN STEEL MOLD CO., LTD |

|

Company Brands |

Manufacturing under the Sa Chen brand |

|

Incorporated Date |

1987 |

|

Business Vision |

Quality first, innovation prioritized, customer focused. |

|

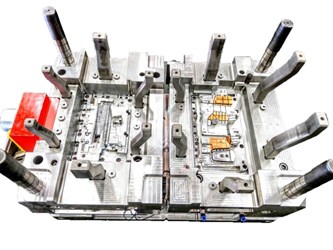

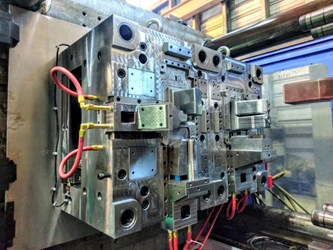

Company Attributes |

1. A professional plastic mold manufacturer engaged in the design, development, manufacturing, and injection molding of various precision plastic molds. 2. Main products include: OA office equipment molds, industrial computer and home appliance molds, communication equipment and mobile phone molds, scanner IC tray molds, double injection molds, mold cooling spiral baffle boards products, USB flash driver molds, automotive plastic parts molds, and optical molds for contact lenses. |

|

Core Capabilities |

Target Market: Focusing on markets with high standards and demands for steel mold products, the ratio of domestic to export sales is approximately equal. Through in-depth market research and exploration of customer needs, the company has not only established a strong presence in the Taiwanese market but has also successfully expanded into international markets such as Japan, Europe, and the United States, earning the trust of global customers. Product Quality: By introducing advanced production equipment and emphasizing technological innovation, the company is committed to providing high-quality and high-precision steel mold products to meet the needs of various industries and customers. It rigorously controls every production process to ensure product accuracy and durability, establishing a strong reputation within the industry. |

|

Future Prospects |

Through continuous improvement and preventive measures, the company ensures enhanced production line yield. It focuses on innovation and technological leadership to achieve sustainable operations. |

SA CHEN primarily engages in the design and development of high-precision injection molds, which are widely applied in industries such as automotive, 3C products and more. Since mold quality is crucial to the overall production efficiency of the manufacturing sector, and with the growing global demand for high-precision molds, SA CHEN has earned high praise from customers by leveraging its strong technical capabilities and innovative solutions to develop and produce various high-quality molds. It is one of the key companies in Taiwan's mold industry.

Target Customers and Markets

In its early years, SA CHEN mainly produced molds for bicycle, 3C products, and camera parts. It later expanded into plastic molds for industries such as semiconductors and automobiles, and more recently entered the green optoelectronics and medical equipment sectors. Since these industries demand high standards for precision, durability, and performance, their requirements for mold quality are extremely stringent. With 37 years of dedication to technology and innovation, SA CHEN has successfully developed over 8,000 types of molds, meeting the needs of these high-standard manufacturers.

SA CHEN’s product designs take various application scenarios into account, continuously researching market demands and adjusting strategies accordingly. In 2007, the company established a factory in Thailand, enabling it to offer optimal solutions to clients in different regions. This has solidified its significant position in the Taiwanese market, while also expanding its reach into international markets.

Leadership and Management Strategy

"Beginning with commitment and ending with integrity" is SA CHEN's unwavering principle. The company’s success is rooted in its founder’s vision of prioritizing quality and staying at the forefront of technology. Since its establishment, the company has been dedicated to building a corporate culture centered on quality and innovation, while swiftly adapting its product lines and business strategies to market trends. The founder understands that continuous innovation is key to maintaining market leadership, thus investing extensively in both software and hardware development. Additionally, SA CHEN places great emphasis on internal management, including actively nurturing talent, supporting employees’ professional growth, and prioritizing employee care. The founder leads with a “people-first” approach, standing alongside employees and offering a variety of training and development opportunities. When employees or their families face challenges, the company extends sincere care and assistance. This atmosphere of mutual trust and stable management instills confidence in employees, fostering a strong sense of loyalty to the company.

Key Technologies and Service Models

To enhance efficiency, SA CHEN has invested in numerous processing and injection equipment, allowing for flexible adaptation to market demands and offering mass production services. Even when challenges arise, the company responds and resolves issues quickly, giving it a competitive advantage in meeting delivery deadlines. In terms of product range, SA CHEN handles everything from small precision molds to large 10-ton molds, providing customized mold solutions.

"Customer first" is one of the company’s core business principles. All product and service quality are aimed at meeting customer needs. The company has implemented the ISO 9001 quality assurance certification system and, in 2019, obtained ISO 13485 certification for medical systems, officially entering the medical equipment industry. SA CHEN strives to ensure that customers receive timely support and assistance throughout product development and use. In 2023, the company also adopted smart production systems (such as ERP and MES) to further enhance customer satisfaction and loyalty.

R&D and Innovation

SA CHEN is committed to innovation, placing great emphasis on it at every stage, from design to customer use. Around the year 2000, the company established a design department in Xiamen to meet the demands of the mainland Chinese market. Today, Xiamen’s design department has become SA CHEN’s innovation hub, providing design support and fostering remote innovation collaboration for the company’s international markets. This has been a key factor in maintaining the company’s leadership in innovation and technology.

With advanced technology, sufficient equipment, and strong R&D capabilities, SA CHEN holds a significant position in the industry. It continually drives technological innovation and product upgrades, working with clients to develop products that exceed industry standards.

Brand Strategy

SA CHEN focuses on mold development and production through OEM (Original Equipment Manufacturing). The company operates under the brand name SA CHEN for contract manufacturing, assisting clients in product development without producing its own branded products. The company's priority is quality and meeting customer needs, rather than building brand awareness. However, due to its excellent design capabilities and product quality, the molds produced by the company have earned a strong reputation in the market and are specifically requested by leading international companies.

SA CHEN began utilizing the internet for marketing 30 years ago, a forward-thinking strategy that significantly enhanced the company’s visibility and helped it attract many new customers. This approach has been a major driver of the company’s growth.

Industry Challenges and Development Strategies

In the face of competition from regions like mainland China, SA CHEN does not prioritize price wars. Instead, it focuses on product design and reliability to attract customers and maintain competitiveness. Looking ahead, as the industry continues to evolve, SA CHEN believes the mold industry should concentrate on producing high value-added molds. Mold design and manufacturing is a complex technical challenge that requires collaboration across multiple departments. While the company has implemented automated production systems to assist with management and manufacturing, it is still difficult to completely replace human labor. With the aging of highly skilled technicians and the growing trend of younger generations being less willing to enter the mold industry, the company has started collaborating with schools to offer vocational training opportunities, hoping to attract more young talent to the field. Lastly, the Taiwanese mold industry frequently faces pricing pressure and strict payment terms. In response to these operational challenges, SA CHEN is working to strengthen its financial structure and enhance its innovation capabilities to gain better negotiating leverage.

Conclusion

The development journey of SA CHEN reflects the evolution and upgrading of Taiwan’s manufacturing industry. From traditional machining equipment to today’s smart manufacturing systems, the company has consistently maintained keen insight into market trends, delivering the most suitable molds for different production needs. This flexible development strategy and sustained efforts have allowed SA CHEN to maintain stable competitiveness in an ever-changing market environment. The success story of SA CHEN is not only a testament to the company’s achievements but also a microcosm of the overall progress of Taiwan's manufacturing industry. Looking to the future, SA CHEN will continue to uphold its commitment to innovation and quality, enhancing its capabilities, exploring new market opportunities, and proactively facing challenges to achieve even greater breakthroughs and accomplishments.

Facebook

Facebook

Twitter

Twitter

LINE

LINE