Shuter Enterprise: Pioneering the Future of Storage with Innovation, Quality, and Sustainability

Table 3-11 Introduction to Shuter Enterprise Co. Ltd.

|

Company Name |

SHUTER Enterprise Co. Ltd. |

|

Company Brands |

SHUTER, livinbox |

|

Incorporated Date |

1969 |

|

Business Vision |

Integrity and excellence, people-centered, joyful work, building dreams with passion |

|

Company Attributes |

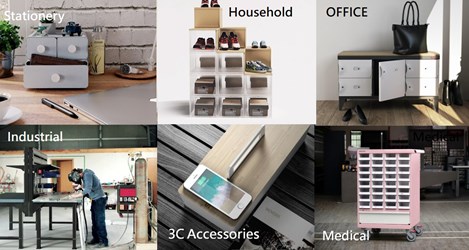

1. The leading storage brand made in Taiwan. 2. Initially began as an OEM manufacturer with a small electronics factory producing timers and related products. Through continuous learning and improvement, the company gradually progressed to establish its own brand. 3. Provides OEM and OBM storage solutions across four major areas: industrial, office, household, and stationery. Products include home storage, efficient file Shuter cabinets, toolboxes, small parts organizer cabinets, and heavy-duty workbenches. |

|

Core Capabilities |

Target Market: Shuter Enterprise is dedicated to providing storage solutions for global customers across various sectors, creating practical and aesthetically pleasing storage products. The target markets include industrial and commercial spaces (such as factories, laboratories, offices, etc.), which have specific needs for storage tools and improving workplace efficiency. Additionally, the personal and home market is also served, with consumers seeking storage products that meet everyday organizational needs while offering quality and aesthetic appeal. Approximately 70% of the company’s products are exported, with key markets being the United States, Europe, and Japan. Product Quality: The products are made from durable and eco-friendly high-quality materials, ensuring a longer lifespan. Throughout the entire manufacturing and shipping process, the company adheres to strict quality management standards to ensure each product meets quality requirements. The company has obtained international certifications such as ISO-50001, ISO-14001, carbon footprint, water footprint, and green eco-label authorization. In addition to guaranteeing product quality, Shuter is committed to energy conservation, carbon reduction, and waste minimization goals. |

|

Future Prospects |

To become a world-class brand representing Taiwan, leading the global trend of humanistic aesthetics and style, making Shuter (SHUTER) visible on the international stage, and proclaiming to the world: "Shuter, made in Taiwan." |

Founder Wu Jing-Lin, known as the "Father of Taiwan Storage Boxes," once taught at Taichung Shuter Industrial College. To honor his roots, he founded Shuter Plastics Factory in 1969, naming the company "Shuter" to signify "Upholding Integrity and Virtue; people-oriented approach." Starting from a modest 10-square-meter parking shed, Wu used a loan of NT$60,000 to purchase processing equipment and began by manufacturing products like chocolate boxes and toys on a contract basis. He even utilized a hot stamping machine to provide customized printing services for clients. His creativity, customer-oriented mindset, and commitment to adding extra value to products have become deeply ingrained in the company culture.

Target Customers and Market

In addition to being popular among domestic consumers, Shuter Enterprise’s products are also exported to over 70 countries worldwide, with exports accounting for 60–70% of the company's total revenue. Key markets include Europe, the United States, and Japan. The company’s official flagship store, "My Shuter Store," combines thousands of physical outlets nationwide with online channels, offering the most comprehensive range of storage solutions. Whether for stationery, household organization, office setups, industrial storage, digital storage, or smart healthcare, consumers can enjoy a one-stop shopping experience at the flagship store.

Leadership and Management Strategy

Chairman Wu Yi-Rui, the successor of Shuter Enterprise, was deeply influenced by his father’s commitment to innovation and pursuit of unique product value from an early age. After returning to Taiwan to take over, he has been bold in reforming existing structures, thinking outside the box, expanding the brand, and fostering a company culture that is cohesive, culturally rich, dream-driven, and grounded in realism.

Shuter Enterprise emphasizes equality among team members, with spacious, uniform seating areas regardless of position level. For significant product development and design decisions, many choices are made by employee vote. The company’s morning meetings often consist of relaxed team activities, while routine meetings are kept brief to avoid monotony, encouraging team-based communication to create a workplace atmosphere filled with creativity and optimism, boosting engagement and sense of belonging among employees.

Shuter is dedicated to being a workplace where employees find fulfillment and a sense of belonging. The chairman advocates breaking down hierarchical barriers, allowing employees ample space to showcase their expertise and creativity. Team members communicate directly with a task-oriented approach in a flat team structure, reducing communication obstacles. He humorously suggests that employees should embody a “pirate spirit”—equipped with professional survival skills, yet more daring, innovative, and action-oriented than a traditional force. By having employees manage and execute projects, the company promotes a sense of responsibility, encouraging collaboration and helping employees recognize and appreciate their value.

Key Technologies and Service Models

Shuter Enterprise focuses on developing its own brand while also providing OEM services for long-term clients. The company’s six key areas—stationery and creative products, household organization, office environment, industrial storage, digital storage, and smart healthcare—release multiple new products every month, achieving levels of efficiency and production unmatched by other companies. To prevent imitation, Shuter invests in developing patented designs that are difficult to copy and has established its own mold factory to precisely control the entire process from design to manufacturing. Skilled technicians are trained to handle details that machines can’t achieve, using hand-finishing adjustments as needed. Shuter’s attention to consumer needs, unique aesthetic design, and durable product quality are the keys to its resilience in a highly competitive market.

R&D Innovation

In 1979, Shuter Enterprise developed the world’s first plastic toolbox under its own brand, replacing costly and heavy metal toolboxes and initiating a materials revolution in storage. Chairman Wu introduced new machinery and innovative technology, reducing labor costs and increasing production efficiency. To meet the needs of the precision industry, Shuter provides ESD (electrostatic discharge) conductive plastic for storing electronic components, with built-in safety features to ensure employee safety. In recent years, Shuter has implemented automated equipment that enhances productivity, reduces pollution, minimizes waste, saves energy, and improves product quality, aligning with the global trend towards a green industry.

Brand Strategy

Shuter Enterprise’s R&D and design team is larger than most in the industry and stands out for its dedication to both product functionality and aesthetic design. The company collaborates with well-known brands like Pixar, DreamWorks, Disney, Marvel, and Hello Kitty, infusing vibrant elements into the traditional industry. Product quality and brand value are non-negotiable principles for Shuter, which avoids low-price competition. Its design standards are world-class, earning recognition through numerous national and international design awards.

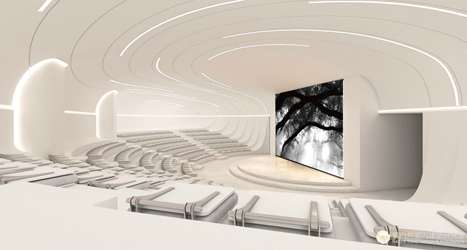

The company’s headquarters is located in the BABBUZA Dream Factory, a green building ten years in the making. It features a spacious, bright, and innovation-friendly office environment, along with an international-grade cultural space—the Shuter People’s Cultural Hall—where employees can enjoy intellectual and artistic enrichment beyond work. The BABBUZA Dream Factory draws on Taiwan’s unique cultural and historical legacy and embodies a spirit of mutual benefit and shared growth, inviting other high-quality Taiwanese brands to create shared experiential spaces. Inside the factory is Asia’s tallest indoor rock climbing wall at 21 meters, with climbing holds modeled after Shuter’s iconic toolbox and other product display units. This unique and immersive design attracts numerous visitors.

Industry Challenges and Development Strategies

Shuter Enterprise’s journey to building its brand has been fraught with challenges, including seven factory relocations, two floods, the 921 earthquake, and a devastating factory fire. Yet, the founder and chairman continued to move forward. To address labor shortages in the traditional industry, Shuter offers a supportive work environment with good benefits and has established a positive professional development system to foster a sense of belonging and accomplishment among employees. In response to the challenge of industrial upgrading, Shuter is proactively embracing digital transformation to adapt to market changes. Leveraging the quality foundations established in its industrial smart cabinets, Shuter is extending these applications into fully intelligent areas, such as smart healthcare.

Conclusion

Shuter Enterprise’s products have transformed consumers' approach to space utilization, demonstrating that efficient storage and new aesthetic elements can seamlessly coexist in everyday life. Throughout its fifty-year journey, Shuter has consistently upheld a commitment to quality and giving back to the community. The company’s Dream Factory has planted seeds of courage and dreams, nourished by the rich culture of this island, and today it stands as a flourishing, vibrant forest.

Facebook

Facebook

Twitter

Twitter

LINE

LINE