Weisheng Wood Foundry Mold: Delivering Exceptional Value in Mold Making through Exquisite Craftsmanship and Innovative Technology

Table 3-10 Introduction to Weisheng Wood Foundry Mold Co., Ltd

|

Company Name |

Weisheng Wood Foundry Mold Co., Ltd. |

|

Company Brands |

Weisheng |

|

Incorporated Date |

1984 |

|

Business Vision |

Provide the highest quality wooden foundry molds and build stable, long-term partnerships with our customers. |

|

Company Attributes |

1. Experts in professional, high-quality wooden foundry mold manufacturing. 2. Specializing in a range of wooden foundry mold contract manufacturing services, including mold design and production, mold processing, mold repair and maintenance, and consulting services related to foundry molds. |

|

Core Capabilities |

Target Market: Our primary customers are domestic machinery manufacturers, and we collaborate closely with foundries to jointly develop high-quality molds, with all products sold within the domestic market. Weisheng Wood Foundry Mold Co., Ltd. maintains a clear market position, dedicated to meeting customer demands for premium wood molds and offering customized solutions tailored to diverse, specialized requirements. Product Quality: Weisheng is committed to exceptional craftsmanship and rigorous quality control to ensure that every product meets the highest standards. Valuing research, development, and innovation, the company believes that production quality should never be compromised for price. We strive to provide our customers with robust, durable, and high-value-added molds. |

|

Future Prospects |

Continuously enhance quality, uphold brand image, and invest in technological research and development to ensure the company's sustainable growth. |

The founder of Weisheng Wood Foundry Mold, Chairman Kun-Jung Lu, currently serves as the 19th President of the Shi Nan Industry and Commerce Association. He graduated from the Wood Mold Department of Changhua Senior Industrial Vocational School, marking the beginning of his over forty-year career in wood mold making. In the early stages of his business, Chairman Lu faced numerous challenges but never backed down. Instead, he established his business philosophy amidst changing times and identified a clear direction for growth. Today, Weisheng Wood Foundry Mold continues to progress steadily in the wood mold industry, supported by extensive experience, precise craftsmanship, and high-quality wooden molds.

Target Customers and Market

Weisheng primarily collaborates with small to medium-sized domestic foundries. Since the wood mold industry operates upstream in the precision machinery sector, machinery manufacturers commission foundries for mold production, which then rely on wood mold companies like Weisheng to create the foundational master molds. While large foundries typically have dedicated personnel for wood mold work, small to medium-sized foundries often outsource this task, making Weisheng an essential partner. Although positioned upstream in the manufacturing process, Weisheng works closely with its clients, emphasizing long-term mutual trust and shared success. Many of the partnering foundries also handle overseas orders, meaning that Weisheng’s technology and quality are ultimately scrutinized by international companies.

Leadership and Management Strategy

In a highly competitive market, some companies maintain a price advantage by cutting material and production costs. However, the founder of Weisheng recognizes that for both domestic and international companies prioritizing quality, key factors in choosing suppliers include technical capability, product quality, and financial stability. Therefore, Weisheng is committed to using high-quality materials and craftsmanship to uphold customer trust and foster long-term relationships. During economic downturns, Weisheng is willing to share the burden by offering moderate discounts and, in special or urgent cases, providing free repair services to reassure and support its clients.

Key Technologies and Service Models

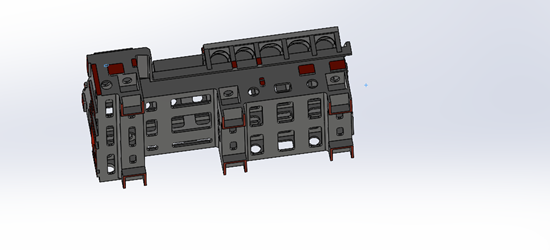

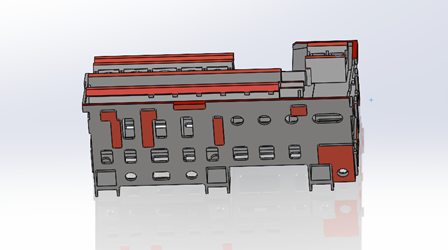

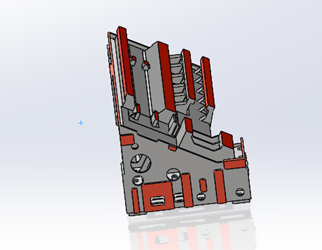

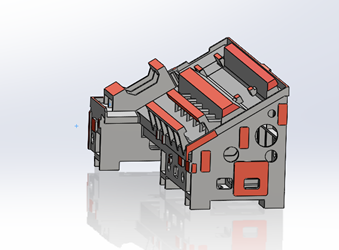

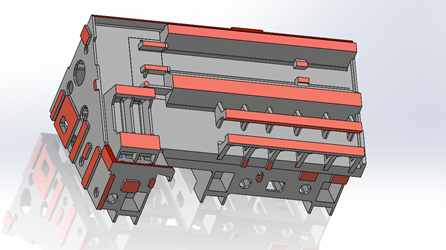

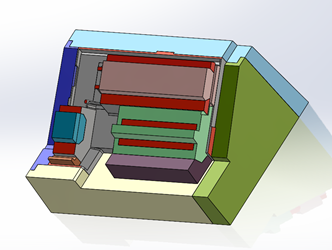

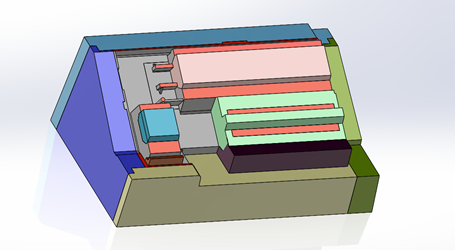

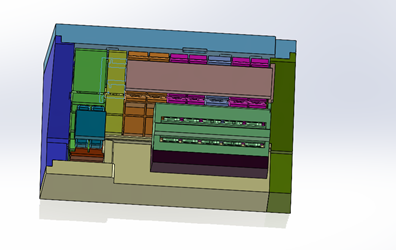

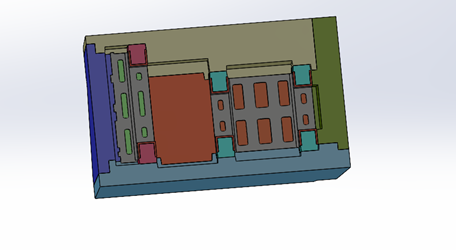

The production of castings relies on a solid wood mold foundation, as the quality of the wood mold is crucial for the smooth operation of subsequent machinery. In earlier commissioned design projects, flat design drawings were standard, requiring wood mold craftsmen to rely on their accumulated experience and refined analytical skills to simulate the internal structure and 3D cross-sections of parts. Although 3D design software now provides assistance, many details still depend on the judgment and adjustments made by experienced wood mold craftsmen.

Each craftsman at Weisheng possesses significant experience and expertise. When faced with various casting solutions and complex client issues, they demonstrate not only strong communication skills and patience but also the technical proficiency to independently and flexibly handle detailed modifications and adjustments to the molds.

R&D Innovation

Mold design is gradually shifting from 2D to 3D rendering, allowing for more detailed designs and reducing error rates in the design of internal assembly structures and moving parts. This approach also facilitates discussions with foundries regarding mold assembly and disassembly details. However, 3D technology still cannot fully replace the precision achieved through manual craftsmanship in the wood mold production process. Particularly for large molds with complex casting shapes, curved and intricate details often require fine-tuning by hand. Weisheng Wood Foundry Mold has a team of highly skilled craftsmen who excel in interpreting and constructing design plans while also being proficient in advanced software. This combination of traditional craftsmanship and modern technology enhances both the precision and efficiency of wood mold production.

Brand Strategy

Weisheng has established its business under its own brand, offering a wide range of products that encompass everything from small parts to large structural components. The company fosters long-term relationships with its clients, providing comprehensive, customized services for wood mold production, maintenance, and repair. With the development of diverse mold materials, Weisheng is also exploring the possibility of expanding into the field of metal mold engraving in the future, investing in new equipment and personnel to further enhance the automation of the entire casting mold process.

Industry Challenges and Development Strategies

Mainland Chinese manufacturers, with their high production speeds, low costs, and increasing technical capabilities, have intensified the pressure on Taiwan’s wood mold companies. In the face of this low-cost competition, Chairman Lu believes that Taiwanese businesses still hold an advantage in advanced technology. However, he emphasizes the need for continuous innovation in high-end products to maintain competitiveness.

Currently, wood mold production largely relies on imported pine or cedar, but material prices are influenced by global factors, which increases cost pressures. Securing high-quality raw materials to meet customer demands while maintaining reasonable profits will test the ingenuity of business operators.

Like many companies in the industry, Weisheng faces a shortage of skilled labor. The sector, especially at the upstream level of mechanical wood mold design, struggles with a lack of new talent, while experienced craftsmen are gradually diminishing. Younger generations are more attracted to high-tech or service industries, making the monotonous environment of wood mold factories less appealing.

The wood mold industry is foundational to the sustainable operations of Taiwan’s machine tool and machinery manufacturers, and the government should take action to address the issue of skills preservation. Although government policies exempt wood mold students from tuition fees, the talent pipeline in this field remains at risk. Large wood mold companies are adopting CNC machining equipment to shorten production times and improve efficiency; however, smaller companies still face challenges related to workspace, manual craftsmanship, and the transfer of experience.

Conclusion

The development of the precision machinery industry is often used as a benchmark for assessing a country's industrial strength, and wood molds are rightly regarded as a critical cornerstone of this sector. Weisheng combines the exceptional craftsmanship of its artisans with advanced design systems and high-precision machining equipment to ensure that every mold meets the highest standards of accuracy. This not only enhances production efficiency but also significantly reduces product error rates. It is hoped that this exquisite craftsmanship will be passed down to the younger generation, ensuring the continued vitality of the wood mold industry.

Facebook

Facebook

Twitter

Twitter

LINE

LINE