Regal Machinery: Combining Precision Craftsmanship with Innovative Technology to Create a Premium Brand of Gear Speed Reducers

Table 3-6 Introduction to REGAL MACHINERY CO., LTD

|

Company Name |

REGAL MACHINERY CO., LTD |

|

Company Brands |

RGL |

|

Incorporated Date |

1992 |

|

Business Vision |

Adhering to the highest standards of 'quality, efficiency, energy-saving, and service' in the production of each finished product. |

|

Company Attributes |

1. Experts in the design and manufacturing of helical gear speed reducers and worm gear speed reducers. 2. In-house production technology has reached 80%, with full control over processes excluding basic engineering tasks like casting, heat treatment, and lathe operations. 3. Initially focused on the software and hardware design and development of worm gear speed reducers, marking a new era in the transmission industry. After years of dedication, the current core business includes the design, development, manufacturing, and sales of worm gear speed reducers and helical gear speed reducers, as well as related components such as hardware, motors, speed changers, and gearboxes. 4. Engaged in the manufacturing and sales of multifunctional hobbing machines, OEM production of worm, worm wheel, and gear components, and grinding wheel grooving services. It is Taiwan's only gear speed reducer manufacturer with capabilities in product manufacturing, OEM services, and equipment manufacturing and sales. |

|

Core Capabilities |

Target market: Focused on developing transmission systems that meet the trends of modern society and the needs of the high-tech and precision equipment sectors, continuously absorbing new knowledge to satisfy customers' ODM requirements. Approximately 60% of sales come from various domestic industries, while the remainder is for export, primarily to the United States and Canada. The company leverages professional technology and customized design to meet customer needs, establishing a solid position in the transmission industry. Product Quality: By leveraging technical expertise, carefully selected material applications, and stringent quality control, the company provides high-precision and reliable products, successfully establishing a good reputation. Typically, the design of products is based on a prior understanding of user needs, making it a competitive advantage in the market, rather than succumbing to malicious price competition. In addition to continuously introducing high-end processing equipment from various countries to improve the in-house production rate, the company actively develops CNC multifunctional worm processing machines from the user's perspective, helping to shorten the lead time for customer development and sampling, thus meeting the procurement needs for reducers, components, and processing equipment. |

|

Future Prospects |

In the current global post-pandemic manufacturing downturn, the company has chosen to focus on learning and advancing towards dual-axis transformation through low-carbon practices and digital technology upgrades, becoming a pioneer in carbon reduction within the gear reducer industry. With the market trend shifting towards low-volume, high-variety demands and the anticipated impact of carbon border tariffs, the company faces intense global competition. To address these challenges, it continuously explores and adjusts new business models, striving to enhance product value and service quality. In the future, the company will continue driving technological innovation and aspires to become the best transmission partner for its customers. Through pragmatic efforts, it aims to gradually achieve its carbon reduction goals and move towards sustainable operations. |

Regal Machinery is a company dedicated to the research, development, and manufacturing of high-precision gear speed reducers. Since its establishment in 1992, the company has prioritized quality and innovation to meet the diverse needs of clients across various industrial sectors. With top-notch design capabilities and production facilities, Regal has built a strong reputation within the industry. Amid the ongoing global shift toward low-carbon manufacturing and digital transformation, Regal is committed to staying at the forefront by continually exploring and adapting new business models to enhance product value and service quality.

Target Customers and Market

Regal Machinery's core products are worm gear speed reducers and helical gear speed reducers, which have a wide range of applications, including lifting and hoisting equipment for ships and construction sites. Due to the high demands for precision and reliability in these industries, Regal has upheld quality as a guiding principle for over 30 years, dedicated to providing customers with suitable solutions.

As customers' requirements for products have become increasingly stringent, Regal has begun developing in-house high-performance worm hobbing equipment and producing key components internally. By manufacturing differentiated products, the company aims to improve customer satisfaction and profitability. In terms of market reach, Regal focuses primarily on the domestic market, with exports to the United States and Canada. The company adopts an open collaboration model, working with various companies to supply each other with unique products, with the goal of capturing more business opportunities.

Leadership and Management Strategy

The founder of Regal Machinery prioritizes quality in business operations, believing that while gear speed reducers and motors are fundamental transmission devices, they are essentially the heart of the entire equipment, with no compromise allowed on material or quality. Consequently, the company insists on thorough inspections for all exports to ensure product quality. The founder also places great importance on operational efficiency, advocating for increased productivity through equipment upgrades, procurement planning, and employee experience development.

For customers, the founder emphasizes maintaining integrity and refraining from competing with intermediaries for clientele. In response to rapid environmental changes and challenges, the Regal team has started focusing on smart development. During the construction and design of the new plant, particular attention is paid to structural safety and production workflow efficiency, as well as leveraging the geographical environment for energy-saving measures. These efforts are aimed at preparing for a future with net-zero carbon emissions.

Key Technologies and Service Models

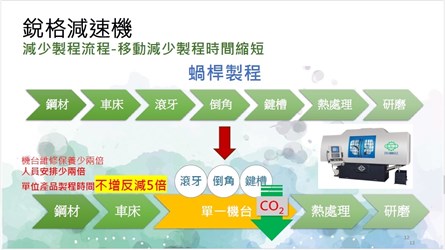

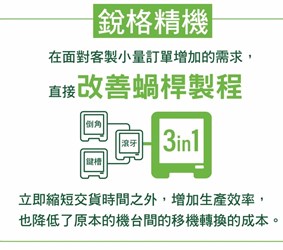

From its early days, Regal Machinery has focused on developing key technologies. To enhance product processing precision, the company imported foreign precision machining equipment, then modified and redesigned it to meet the needs of Taiwanese businesses. In 2011, Regal successfully developed a CNC composite thread rolling machine, enabling the company to complete client-commissioned development projects more quickly and efficiently, thus shortening the sample development process and establishing a competitive advantage.

Regal’s sales promotion primarily relies on distributors or agents to sell standard products, providing customers with timely, local service. For custom-spec products, orders are handled through trading intermediaries or overseas agents and then resold to international customers. In Taiwan, Regal offers customized service by working directly with equipment clients to ensure products are in optimal condition. Besides providing gear reducers, Regal also assists clients in designing and manufacturing custom transmission products tailored to various end-use applications, helping them enhance their competitive edge.

R&D Innovation

The founder of Regal Machinery has consistently driven product innovation. Over a decade ago, the company developed an in-house thread rolling machine, which successfully entered the quality-demanding Japanese market. Regal not only emphasizes quality and equipment aesthetics but also leads the market by including oil mist filters as standard features, giving equal importance to production details, environmental protection, and operator health. This approach has gradually expanded the company’s market presence.

Today, Regal Machinery is the only company globally capable of synchronously performing three processes on a single machine, creating customized equipment based on client needs and integrating multifunctional processes to improve production efficiency. The founder is not only open to sharing technical knowledge with employees but also actively evaluates the impact of smart technologies on production. Through digital transformation, Regal aims to enhance productivity and ensure sustainable development.

Brand Strategy

Regal Machinery uses "RGL" as its trademark. Over the years, through marketing by exceptional domestic and international partners, or by clients rebranding products under their own labels, RGL has successfully penetrated countless markets worldwide. Honed through countless trials, the company has firmly established its quality reputation, earning customers' trust and recognition.

Regal upholds quality, integrity, professionalism, and innovation as its core values, shaping a strong brand image. Looking ahead, the company plans to flexibly adjust the balance between standardized and customized products to meet evolving market demands, striving to fulfill customer needs while expanding its potential customer base.

Industry Challenges and Development Strategies

To address changing demands across regional markets, Regal Machinery adopts flexible strategies. For example, in China and India, the company promotes multifunctional equipment to support the high-volume production models prevalent in these areas. In the European market, it takes an OEM approach, positioning itself as a key component supplier for green manufacturing.

Additionally, talent shortages have long challenged the traditional manufacturing sector, with young professionals often preferring emerging, popular industries, making it difficult to close the workforce gap in manufacturing. Factors like price competition, exchange rates, tariffs, and international politics create complex challenges that threaten industry growth and necessitate stronger government policy support. Finally, as the company undergoes a rigorous transformation, it must invest in advanced equipment to enhance competitiveness, hoping the government will carefully consider the costs associated with land reclassification.

Conclusion

For years, Regal Machinery has upheld its business philosophy centered on quality, efficiency, energy conservation, and service. Through lean management, a commitment to pragmatic carbon reduction, proactive industry engagement, and clear development strategies, the company has established a strong foothold in a competitive market. By advancing professional and green manufacturing technologies and fostering communication to understand customer needs, Regal addresses industrial application challenges effectively.

Looking to the future, Regal aims to maintain a technological edge through low-carbon manufacturing and smart production. With international buyers increasingly prioritizing ESG standards, Regal believes that corporate social responsibility should start within its own facilities. The company conducts internal carbon audits, integrates carbon emission tracking technology, actively implements plant-wide energy monitoring systems, and progressively invests in a CMB process carbon footprint tracking and calculation system. Additionally, as the founding member of the Low Carbon Industry Alliance (LCIA), Regal is committed to supporting the development of domestic industry.

Facebook

Facebook

Twitter

Twitter

LINE

LINE